Tube Bending & Shaping Services

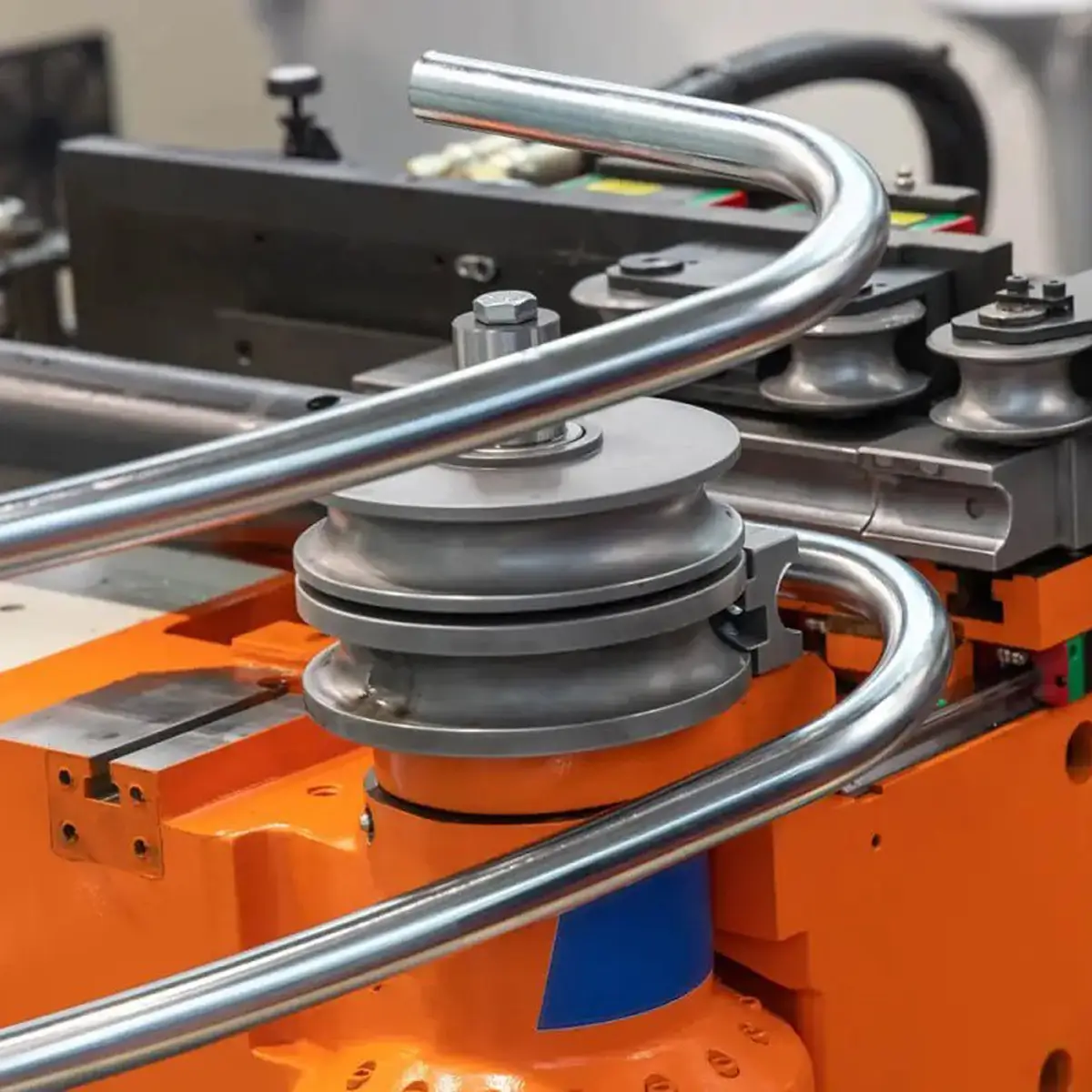

KKraft RADIX transforms straight tubes and pipes into precise, structurally sound components. Our tube bending and shaping service is essential for creating everything from custom vehicle roll cages and exhaust systems to architectural handrails and industrial pipework. We use advanced bending techniques to ensure smooth, wrinkle-free bends that maintain the material’s strength and integrity. We utilize a combination of mandrel benders and roll benders to achieve a wide variety of shapes and sizes with consistent quality.

Capabilities

Material Shapes

- Round

- Square

- Rectangular (RHS/SHS) Tubing

Maximum Diameter (Round Tube)

Up to 76.2 mm (3 inches)

Bending Method

CNC Mandrel Bending for tight radii and wrinkle-free results

Maximum Size (Square Tube)

Up to 10 mm x 10 mm

Why Choose KKraft RADIX Bending Services?

-

Structural Integrity: Unlike “cut-and-weld” elbows, a bent tube has a continuous grain structure, making it significantly stronger and more reliable under stress and vibration.

-

Flawless Finish: Our use of internal mandrels and wiper dies prevents common defects like wall collapse (ovality), wrinkling, and tool marks, resulting in a professional, aesthetically pleasing finish.

-

Cost-Effective for Production: For projects requiring multiple identical parts, our CNC process is highly repeatable and much faster than manual fabrication, saving you time and money.

-

Engineering Expertise: We understand the physics of bending—how to account for material springback and calculate the correct bend radius to avoid material failure.

What Bending Involves

For high-quality bends, we use a process called mandrel bending. The tube is securely clamped and then drawn around a rotating bend die. A flexible, ball-shaped tool called a “mandrel” is inserted inside the tube to support the inner wall, preventing it from collapsing or wrinkling as it’s being formed. Materials We Bend

- Mild Steel & ERW Tube

- Stainless Steel Tubing (Ideal for food-grade and aesthetic applications)

- Aluminum Tubing

- Structural Sections (CHS, SHS, RHS)

Always ask if they use a mandrel bender for tight radius bends. A provider without one may produce flattened, weakened, or wrinkled bends. Inquire about their tooling inventory; having the correct die and mandrel size for your specific tube diameter and wall thickness is crucial for a quality result.

Advantages Over Other Methods

- vs. Welded Fittings/Elbows: Bending provides superior strength, a cleaner look without weld seams, and is often cheaper and faster as it reduces labor and consumables (no cutting, grinding, or welding rods needed).

- vs. Hot Bending/Forging: Cold tube bending is faster, more precise, and doesn’t alter the material’s surface finish or metallurgical properties with heat.

FAQs On Tube Bending & Shaping

What is the tightest bend radius you can achieve?

This depends on the tube’s diameter, wall thickness, and material type. A common rule of thumb is a centerline radius of 1.5 to 2 times the tube diameter, but we can often go tighter. Contact us with your specs to discuss.

Can you bend solid bar stock?

Yes, we also have the capability to bend solid round and square bars. The parameters are different from hollow tubing, so please consult with us.

Do I need to provide a CAD file?

A CAD file (like .STEP or .IGES) is ideal for complex parts. However, we can also work from detailed drawings with specified angles, radii, and lengths.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.