Hydraulic Metal Cutting Services

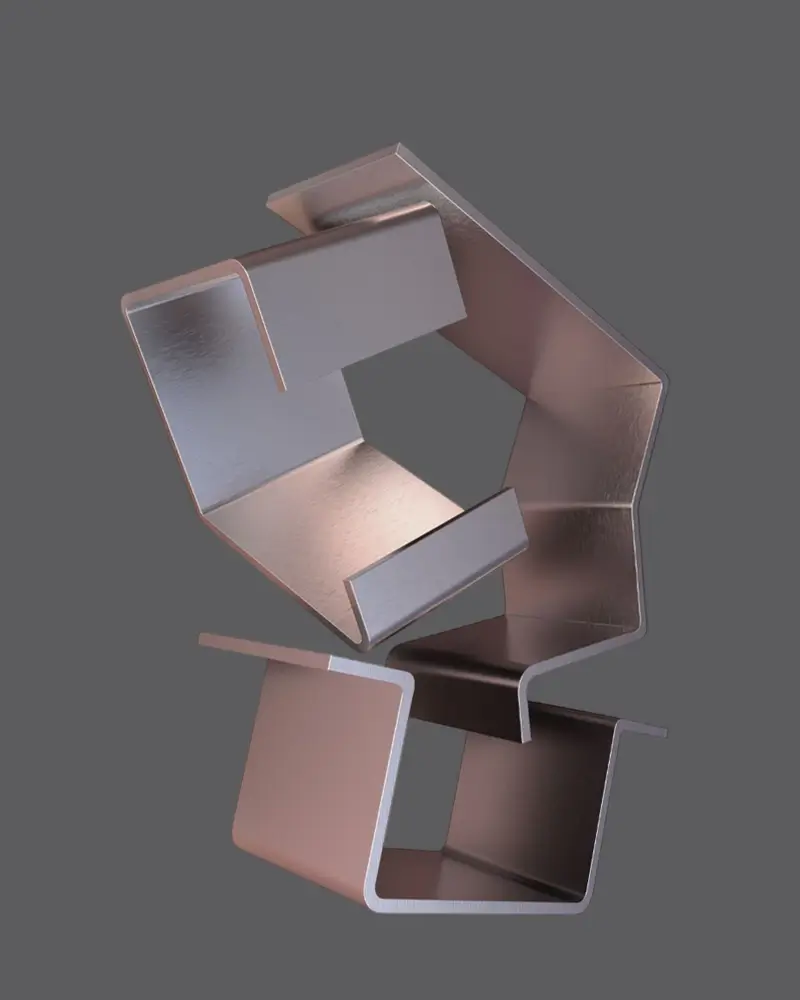

Our hydraulic press bench cutting service, also known as shearing, is the cornerstone of efficient metal fabrication. It’s designed to deliver clean, straight-line cuts on sheet and plate metal with exceptional speed and accuracy, providing the perfect starting point for any high-quality project. We turn raw stock into precisely dimensioned blanks, ready for the next stage of production. Our workshop is equipped with a high-tonnage hydraulic shear capable of handling a wide range of materials and dimensions. We pride ourselves on tight tolerances and pristine results.

Capabilities

Tonnage Capacity

Up to 250 tons

Typical Tolerance

+- 14 mm

Maximum Thickness

Mild Steel: Up to 12 mm

Stainless Steel: Up to 6 mm

Aluminium: Up to 6 mm

Why Trust Us with Your Cutting Needs?

-

Burr-Free Edges: Our machine’s blades are meticulously maintained and calibrated to produce exceptionally clean cuts with minimal burring, reducing the need for secondary finishing operations.

-

Speed & Cost-Effectiveness: For straight-line cuts, hydraulic shearing is significantly faster and more economical than laser or plasma cutting, especially for high-volume orders.

-

No Heat-Affected Zone (HAZ): Shearing is a cold-cutting process. This means the material’s structural integrity and metallurgical properties at the edge are not compromised by heat, which is a critical factor for subsequent welding or forming.

-

Engineering Oversight: Every job is reviewed by our engineering team to ensure optimal material utilization and adherence to your project’s specifications.

What Hydraulic Cutting Involve?

Materials We Frequently Shear

- Carbon & Mild Steel (e.g., A36, 1018)

- Stainless Steel (e.g., 304, 316L)

- Aluminum (e.g., 5052, 6061)

- Brass & Copper Sheet

When selecting a workshop, ask about the sharpness of their blades and their blade gap calibration. A dull blade or incorrect gap will cause material to deform or create a rough, angled edge instead of a clean cut. Also, inquire about their clamping system to ensure your material won’t slip during the cut, guaranteeing accuracy.

Advantages Over Other Methods

-

vs. Plasma/Laser Cutting: Shearing is faster and cheaper for straight cuts and produces no Heat-Affected Zone.

-

vs. Abrasive Saw Cutting: Shearing is much faster, cleaner (no dust or sparks), and produces a smoother edge that typically requires less deburring.

FAQs On Steel Metal Cutting

Can you cut shapes other than rectangles?

Our hydraulic shear is specialized for straight-line cuts only. For complex profiles, we would recommend a different process like plasma or laser cutting.

What information do you need for a quote?

We need the material type, thickness, dimensions of the final pieces, and the total quantity required. A simple drawing or cut list is perfect.

Will my material get scratched?

We use material hold-downs designed to secure the sheet firmly without marring the surface. For delicate materials, we can take extra protective measures.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.