In short, MIG welding is like using a hot glue gun—it’s fast, relatively easy to learn, and great for thicker metals. TIG welding is more like fine-point calligraphy—it’s slower, requires more skill, and produces precise, beautiful welds, especially on thin materials. Neither is better than the other; they are simply different tools for different jobs.

Let’s break down the two most common welding methods to see what truly sets them apart.

A Tale of Two Welds: The Core Differences

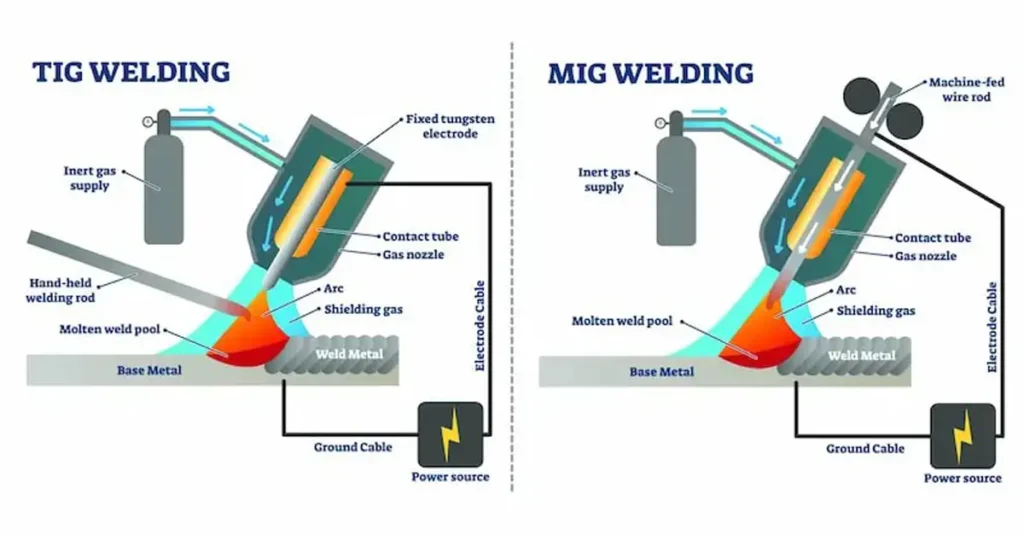

Both Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) welding were developed in the 1940s to tackle the challenge of joining tricky metals like aluminum and magnesium. They both use an electric arc and a shielding gas to create a weld, but how they go about it is fundamentally different.

- Speed vs. Precision: If you need to lay down a lot of weld quickly, MIG is your sprinter. Its semi-automatic process makes it ideal for production and thicker projects. TIG is the marathon runner, demanding a slower, more deliberate pace that rewards you with incredible precision and control.

- The Tools of the Trade: This is the biggest mechanical difference. MIG welding uses a continuously fed, consumable wire electrode that melts to become part of the weld itself. TIG, on the other hand, uses a non-consumable tungsten electrode to heat the metal, while you manually add a separate filler rod with your other hand.

- The Look and Finish: TIG welding is famous for producing clean, aesthetically pleasing, “stack-of-dimes” welds. It’s the top choice for projects where looks matter. MIG welds are strong and functional but are generally less refined in appearance.

Under the Hood: A Process Breakdown

While the end goal is the same—joining metal—the journey there has some key distinctions.

A. Electrode

The electrode is at the heart of the difference.

- MIG (GMAW): Uses a wire spool that is continuously fed through the torch. This means you can essentially weld with one hand, pointing and pulling the trigger. The wire acts as both the electrode and the filler metal.

- TIG (GTAW): Requires two hands. One hand holds the TIG torch with its durable tungsten electrode, and the other hand carefully feeds a filler rod into the molten weld pool. This two-handed operation gives you pinpoint control over how much filler is added and where.

B. Shielding Gas

The gas protects the molten weld pool from contamination by atmospheric gases like oxygen and nitrogen.

- MIG welders most often use a mix of **argon and carbon dioxide (CO₂) **. The CO₂ provides deeper penetration, which is perfect for thicker materials. Gas flows at a higher rate, typically 35-50 cubic feet per hour (CFH).

- TIG welders typically use pure argon or an argon/helium mix. This provides a very stable, clean arc, which is essential for the high-quality finish TIG is known for. The gas flow is lower, around 15-25 CFH.

C. Power Source

- MIG almost exclusively uses a Direct Current (DC) power source. This provides a stable arc and smooth metal transfer.

- TIG is more versatile, using both DC and Alternating Current (AC). DC is used for steels and other ferrous metals, while AC is essential for aluminum. The alternating current has a cleaning effect that breaks through the tough aluminum oxide layer that forms on the metal’s surface

Choosing Your Weapon: Which Process for Which Metal?

While you can weld most metals with either process, one is often a much better choice.

- Mild Steel and Cast Iron: MIG is the workhorse here. It’s fast, efficient, and creates strong welds. Since these projects are often painted or coated, the aesthetics of the weld bead are less of a concern.

- Stainless Steel: For precision work where you want to minimize heat input to prevent warping, TIG is the clear winner. Its control allows for neat, narrow welds. However, for mass production of stainless steel parts, MIG is often used to speed things up.

- Aluminum: TIG is king for aluminum. The ability to use AC power to clean the oxide layer is a game-changer. It allows for precise, high-purity welds without spatter, which is crucial for thinner aluminum stock.

Real-World Scenarios: Where They Shine

Let’s move beyond the metals and look at the job itself.

| Scenario | Best Choice | Why? |

| Thick Materials | MIG | Offers deeper penetration and a faster deposition rate, making it perfect for structural steel, heavy equipment repair, and manufacturing. |

| Thin Materials | TIG | The excellent heat control (often via a foot pedal) prevents you from blowing holes through delicate sheet metal. Ideal for aerospace, automotive bodywork, and pipe welding. |

| Aesthetics are Key | TIG | When the final look is as important as the strength (e.g., custom furniture, sculptures, high-end automotive parts), TIG’s clean finish is unmatched. |

| Speed & Production | MIG | In a production environment where time is money, MIG’s semi-automatic nature allows for rapid, repeatable, and strong welds. |

| Awkward Angles | MIG | The one-handed “point-and-shoot” operation makes it easier to get into tight or unusual positions, as your other hand is free to support you or the workpiece. |

| Beginner Friendliness | MIG | MIG is significantly easier to learn. A beginner can be laying down decent, functional beads in a very short amount of time. TIG requires much more practice and coordination. |

The Final Verdict

The debate over MIG vs. TIG isn’t about which one is “better”—it’s about choosing the right tool for the job.

Think of it this way: you wouldn’t use a sledgehammer to hang a picture frame. Similarly, you wouldn’t choose the slow, deliberate process of TIG for welding a massive steel beam.

- Choose MIG for speed, simplicity, and efficiency, especially on thicker steel.

- Choose TIG for precision, quality, and beauty, especially on thinner materials and non-ferrous metals like aluminum.

Becoming a truly versatile welder means understanding the strengths and weaknesses of both. Knowing when to grab the MIG gun and when to pick up the TIG torch is what separates a good welder from a great one. For the best quality plasma welding and other types of joinery welding, reach out to KKraft RADIX at +254 736 900 111 or email us at steel@kkraftradix.com for more details.