CNC Machining Services

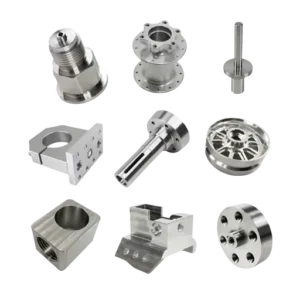

At KKraft RADIX, we deliver world-class CNC machining services in Kenya that keep your production running smoothly as your business grows. Our experienced Project Engineers partner with you through every stage—from CNC design and prototyping to production and delivery—ensuring each project meets the highest precision machining and cost-efficiency standards.

Whether you need small-batch prototypes or large-scale production runs, KKraft RADIX is your trusted partner for CNC milling, CNC turning, and custom machined parts across Kenya and beyond.

Our CNC milling services deliver exceptional accuracy and finish across both wood, metal and plastic parts, supporting industries such as manufacturing, automotive, energy, and engineering.

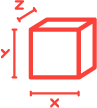

Capabilities

Maximum Dimensions

11,500 * 1,500 * 2,500 mm

Available Materials

Plastics: Nylon, PE, POM, PP

Wood

Why Choose KKraft RADIX for CNC Machining in Kenya?

- Scalable Production: Grow your business confidently—our facilities handle everything from one-off prototypes to mass production orders.

- All-in-One Service: We manage every step, including design review, instant quoting, machining, finishing, inspection, and delivery.

- Simplified Project Management: Work with one dedicated project contact for smooth communication and faster results.

- Fast Quotes & Lead Times: Get real-time quotes and short turnaround for CNC prototyping and low-volume manufacturing.

CNC Milling Services

Our CNC milling service in Kenya uses state-of-the-art technology to produce high-quality parts with tight tolerances and excellent surface finishes. Unlike drilling, CNC milling can move in multiple directions, allowing for complex geometries and custom designs.

At KKraft RADIX, we utilize advanced 5-axis milling machines and live tooling systems that perform multiple operations in a single setup—minimizing production time while maintaining consistency. This makes our precision CNC milling ideal for both prototypes and full production orders.

CNC Turning Services

We also offer sliding head CNC turning, which significantly reduces cycle times and production costs compared to conventional fixed-head machines. Whether you need metal machining or plastic turning, KKraft RADIX ensures precision and reliability in every piece.

CNC turning capabilities:

- Maximum Length: 3,845 mm

- Maximum Diameter: 950 mm

- Available Materials:

Metals: Steel, Stainless Steel, Aluminum, Titanium, Copper

Plastics: Nylon, PE, POM, PP

CNC Machining Design Tips

Follow these design best practices to enhance manufacturability and reduce CNC production costs:

- Add Radii to Internal Edges: Use internal radii about 130% of the milling tool’s radius for better results.

- Avoid Thin Walls: Thin features can vibrate or deform during cutting.

- Apply Tolerances Wisely: Only specify tight tolerances when necessary—standard ISO 2768-m tolerances are often sufficient.

- Simplify Geometry: Eliminate unnecessary or unmachinable features.

- Maintain Ideal Cavity Ratios: Keep cavity depth no more than 4 times its width.

- Limit Thread Length: A length 3× the thread diameter provides sufficient strength.

- Use Standard Hole Sizes: Standard drill bit sizes reduce time and machining costs.

By applying these CNC design guidelines, you’ll achieve faster turnaround, lower costs, and superior results.

CNC Prototyping Services in Kenya

Our CNC prototyping services enable the rapid production of high-precision prototypes using a wide range of materials. CNC machining is ideal for creating functional prototypes that match the strength, durability, and accuracy of final production parts—unlike 3D printing or molding processes that are often limited to visual models.

Because CNC machining requires no fixed tooling, it allows for quick design iterations and easy modifications. This flexibility makes KKraft RADIX the top choice for rapid CNC prototyping in Kenya, supporting industries from engineering to product development.

We work with diverse metals and plastics, helping you test material performance and optimize your designs before moving into mass production.

CNC Machining Services FAQs

How can I reduce the cost of CNC machined parts?

CNC part pricing depends on machining time, material type, setup costs, and geometry.

To lower your costs:

- Simplify your design and reduce unnecessary tight tolerances.

- Choose easy-to-machine materials.

- Increase order volume to spread setup costs.

Our engineers can help you optimize your design for cost-effective CNC manufacturing.

Do you offer manufacturing consultation?

Yes. Our expert manufacturing engineers provide technical guidance and recommendations to help you achieve optimal results at the lowest cost.

How much do CNC machining services cost?

Pricing depends on material, complexity, and production volume. Our experienced engineers evaluate your design and provides accurate lead times and costs based on real manufacturing data.

Do you machine plastics and wood?

Yes. We work with a broad range of metals and plastics, including steel, aluminum, titanium, PE, POM, nylon and even select wood materials for specialized CNC projects.

Do you have 5-axis CNC milling machines?

Absolutely. KKraft RADIX operates advanced 5-axis CNC milling machines capable of handling the most complex parts with unmatched precision.

What quality standards do you follow?

All machining is performed in accordance with ISO 9001 and EN 10204 standards. Our internal Quality Engineers perform rigorous inspections to ensure your parts meet the highest international standards.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.