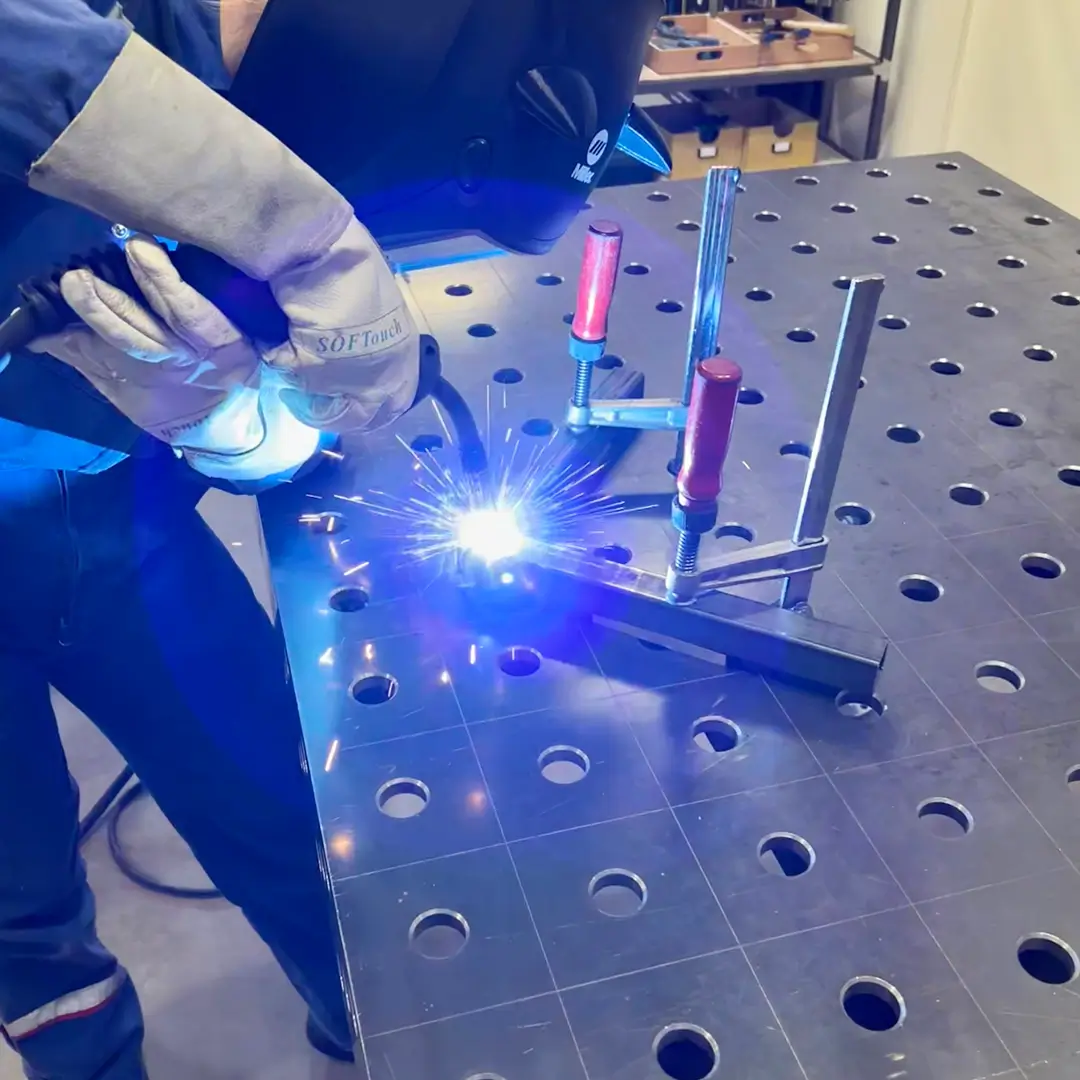

Plasma Welding Services

KKraft RADIX’s assembly and welding services ensure your growing needs never outpace your production capabilities. Our project engineers are ready to assist in planning and execution, making certain your projects are completed cost-efficiently and to high-quality standards.

Our capabilities include a wide array of welding processes and we’re offering various techniques to finalise assemblies to the desired stage of completion. Our fastening solutions include but are not limited to bolts, nuts, weld bolts, weld nuts, TOX, blind rivets, rivet nuts, and press bolts.

Capabilities

Available Processes

TIG welding

Spod welding

Soldering

Brazing

Maximum Materal Thickness

Carbon Steel 20mm

Stainless Steel 20mm

Aluminium 20mm

Why Get Plasma Welding Services From KKraft RADIX?

Our team boasts more than 10 account managers experienced in the manufacturing industry with a focus on being a business partner rather than just a subcontractor.

KKraft RADIX has a wealth of experience, providing services for a wide range of engineering industries, including clients from industrial automation, aerospace, construction, etc.

MIG/MAG Welding Services

Probably the most common welding process in engineering, MIG creates an electrical arc between a filler material (electrode in the spool gun) and the metal that acts as a cathode. The arc creates heat to melt the electrode wire while the shielding gas protects the molten metal from atmospheric elements. Once the heat gets removed, it solidifies and becomes a weld.

MIG welding (also known as GMAW or Gas Metal Arc Welding) services are a very common way for joining two metals. Its strength comes with the variety of metals suitable for MIG/MAG as well as the high max thickness capabilities while maintaining high quality.

TIG Welding Services

TIG welding services use a pointed tungsten electrode that creates an intense arc. This allows for great accuracy that is much needed for high-quality precision welding.

TIG welding process (also known as GTAW or Gas Tungsten Arc Welding) uses a non-consumable tungsten electrode, meaning that it melts the base metal (the electrode itself does not melt). When filler metal is required, it must be added separately to the weld pool. Similarly to MIG, shielding gas is used to protect the weld.

This process allows for very high quality but also puts more requirements on the metal and the cleanliness of the weld and working area. It is most suitable for stainless steel and aluminium welding.

FAQs On Plasma Welding & Assembly

Can I bring my own parts for welding?

We only work with projects whereby KKraft RADIX takes care of the whole process, including the manufacture of parts.

What metals can you weld?

Do you do the work in-house?

What welding technology would suit our needs?

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.