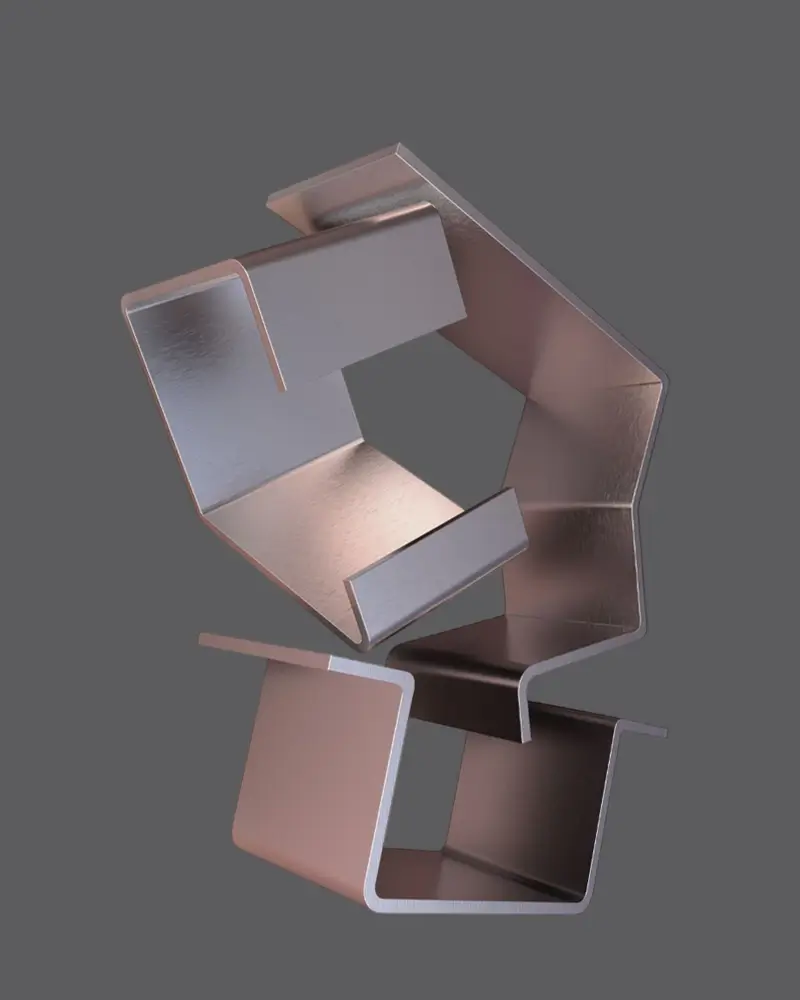

Metal Bending Services

Metal folding services by KKraft RADIX ensure your growing needs never outpace your production capabilities. Our Project Engineers are ready to assist in planning and execution, making certain your projects are completed cost-efficiently and to high quality standards.

Capabilities

Available Processes

Up to 1000 tons

Maximum Materal Thickness

Up to 10 mm

Maximum Bending Length

Up to 2440 mm

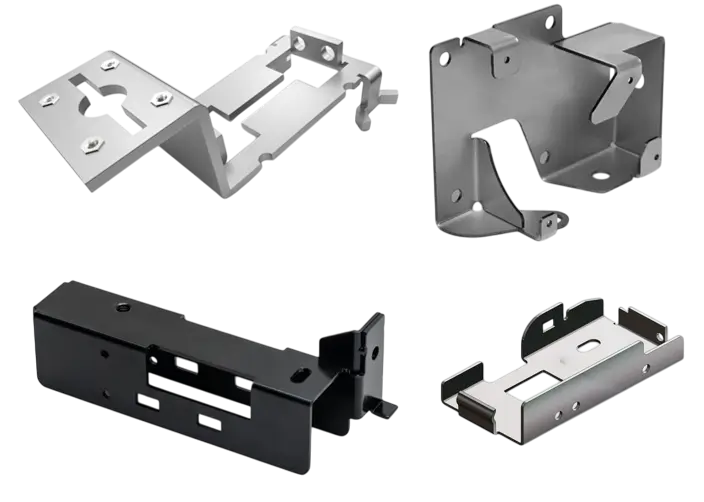

What is Metal Folding?

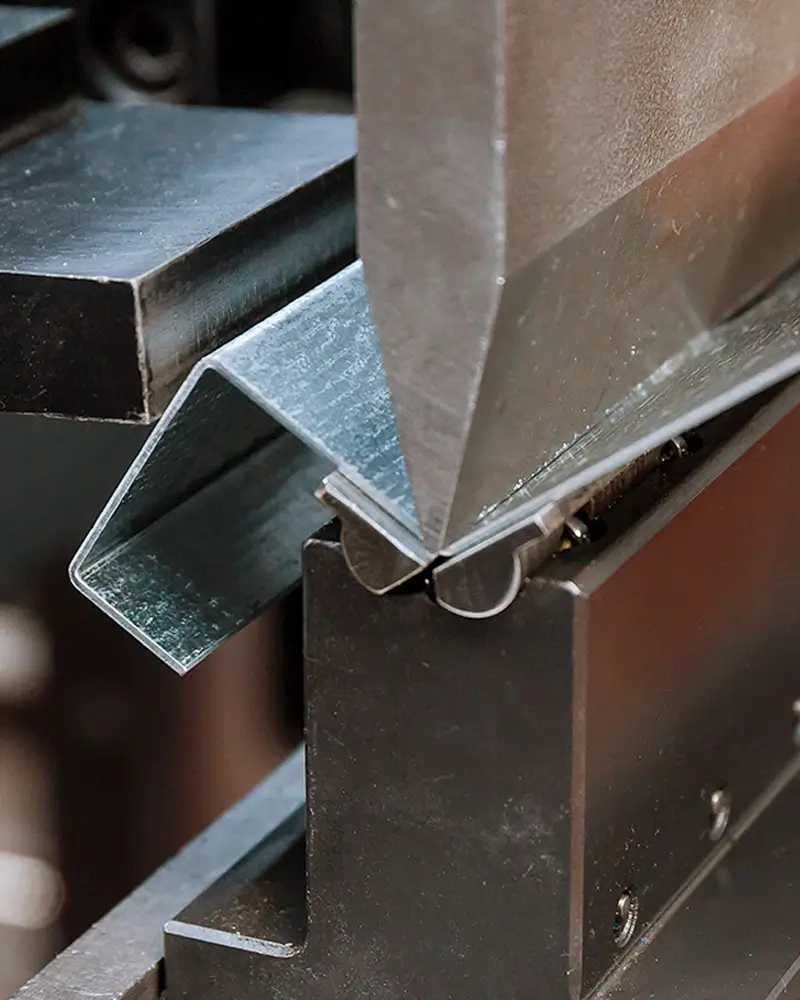

Sheet metal folding is a very common forming method used to give the desired shape to structural steel, stainless steel, aluminium, etc. parts. A press brake is used to give the final shape to a part. It is important to bear in mind that bending is performed after the cutting process. Therefore, you have to keep some design tips in mind.

Metal bending is possible for sheets (up to 6 mm) as well as plates (anything above). The possibility of executing a job depends on the manufacturer’s capabilities – maximum bending edge length and pressing force. Thicker materials and longer bending lines need more force. Whereas 200-ton pressing force is enough for most jobs – it can, for example, bend a 2 m line with a 10 mm thickness – you sometimes need more.

A variety of bending methods exist to do the job. Although most of them are suitable for the average job, each has some specific use-cases and needs different press brake tooling. Here’s a list of possibilities to make your life easier when looking for a metal folding service.

- V-bending – The most widely spread folding method where a punch presses the sheet metal onto a die. V-bending has 3 divisions – air bending, bottoming and coining. Air bending is the most common of them. There, the sheet is not pressed onto the die but rather some way towards it until the desired angle is achieved.

- U-bending – Quite similar in terms of using a punch and die. Instead of a V-shape, it uses a U-shape. Thus, its main use is to produce U-channels.

- Step bending – Uses successive V-bending to achieve large-radius bends. Smaller steps assure better and smoother quality.

- Roll bending – A bending method that uses rolls instead of punches and dies. Great for producing parts with large radii or conical sheet metal details.

- Rotary bending – Another bending technique to produce angular bends. The big advantage over other methods is the lack of bending marks (usually left by the V-shaped die) on the part.

Metal Folding Advantages

While welding is inevitable in many cases and bending cannot substitute it everywhere, we recommend choosing metal bending services whenever possible. The advantages of metal folding are:

- Aesthetics – Although in engineering functionality comes first, design follows closely behind. The lack of weldments guarantees a nice visual for your project.

- Coating – A smooth surface is a great canvas for coating procedures, leaving a better result.

- Fewer Mistakes – Welding needs more manual labour. Manual labour, in turn, leaves more room for mistakes. Automatic CNC bending systems provide accurate results.

- Fewer Parts – It is more convenient to re-work your parts in CAD, if needed. But it’s also easier to keep your workfloor nice and tidy with fewer parts laying around.

FAQs On Steel Metal Folding

What file formats do you accept for designs?

How does material type affect the bending process?

Different materials have unique properties that influence how they bend. For example:

- Ductility: Materials like mild steel and aluminum are more ductile and bend easily without cracking.

- Springback: All materials have a tendency to partially return to their original shape after being bent. Harder materials like stainless steel have more springback than mild steel, which requires us to over-bend the part slightly to achieve the target angle.

- Grain Direction: Bending along the material’s grain can sometimes lead to cracking, especially with certain aluminum alloys. We account for this during the layout and cutting phase.

It’s vital to specify the exact material and grade you need so we can adjust our process accordingly.

What is the minimum flange length you can create?

The minimum flange length (the length of the bent edge) depends on the material thickness, the bend radius, and the tooling we use. A good rule of thumb is that the minimum flange length should be at least four times the material thickness. For example, for a 2 mm thick sheet, the flange should be at least 8 mm long. Designing a flange that is too short can cause the material to slip in the die, resulting in an inaccurate and distorted part.

What welding technology would suit our needs?

The bend radius is the inside radius of the bent corner. Choosing the correct bend radius is critical to prevent material cracking or deformation.

- Too Sharp: A radius that is too small for a given material thickness can cause stress fractures on the outer surface of the bend.

- Ideal Radius: As a general design tip, an inside bend radius equal to the material thickness is often a safe and effective choice for most metals.

If your design requires a specific radius, please indicate it clearly in your drawings so we can select the appropriate tooling to achieve it.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.