Sheet Metal Punching Services

At KKraft RADIX, precision is at the heart of everything we do. Our Metal Punching service combines advanced machinery, expert craftsmanship, and innovative technology to deliver consistent, high-quality results for a wide range of industries.

Whether you’re in automotive, construction, electrical, HVAC, or manufacturing, our punching solutions are tailored to meet your exact specifications. We understand that every client’s needs are different. From small prototype runs to high-volume production, which is why RADIX offers flexible, cost-effective, and scalable punching services designed to enhance your fabrication process and reduce lead times.

When you partner with KKraft RADIX, you’re not just getting a service, you’re getting a fabrication partner dedicated to precision, performance, and perfection.

Our machines can perform punching, nibbling, embossing, notching, and forming operations — giving you complete flexibility in your sheet metal design and production.

Capabilities

Maximum Dimensions

1,500 mm * 4,000 mm

Material Handled

- Mild Steel, Aluminum, Brass, Copper, Galvanized Steel, Stainless Steel

Maximum Material Thickness

Up to:

-

- Steel – 6 mm

- Aluminum – 5 mm

- Stainless Steel – 3 mm

Hole Diameter Range

1 mm – 100 mm

Accuracy

±0.1 mm

Why Choose KKraft RADIX for Sheet Metal Punching?

- Precision Engineering: We use state-of-the-art CNC punching machines that guarantee dimensional accuracy and consistent hole quality.

- Custom Solutions: Every project is customized — from tooling selection to punch programming — to suit your product’s design and material.

- Efficiency & Speed: Our automated systems ensure quick turnaround times without compromising quality.

- Material Versatility: We handle a wide range of metals and thicknesses, providing you with flexibility for different applications.

The Metal Punching Process

Metal Punching is a fabrication technique where a CNC-controlled punch press uses hardened tools to perforate or shape metal sheets with extreme accuracy.

- Design & Programming: We start with your CAD drawing or design file, which is converted into CNC code for precise tool paths.

- Tool Setup: The correct punch and die sets are selected based on material type, thickness, and hole geometry.

- Punching Operation: The machine applies high pressure to punch holes or cutouts into the sheet metal.

- Quality Check: Every part is inspected for accuracy, burrs, and consistency before moving to the next fabrication stage.

This process ensures repeatable accuracy, minimal waste, and excellent edge quality for downstream operations like bending, welding, or assembly.

Applications of Sheet Metal Punching

Metal punching is a key process in modern manufacturing. It’s used in the creation of:

- Electrical enclosures and panels

- Architectural metalwork

- HVAC duct components

- Automotive brackets and chassis parts

- Machine guards and housings

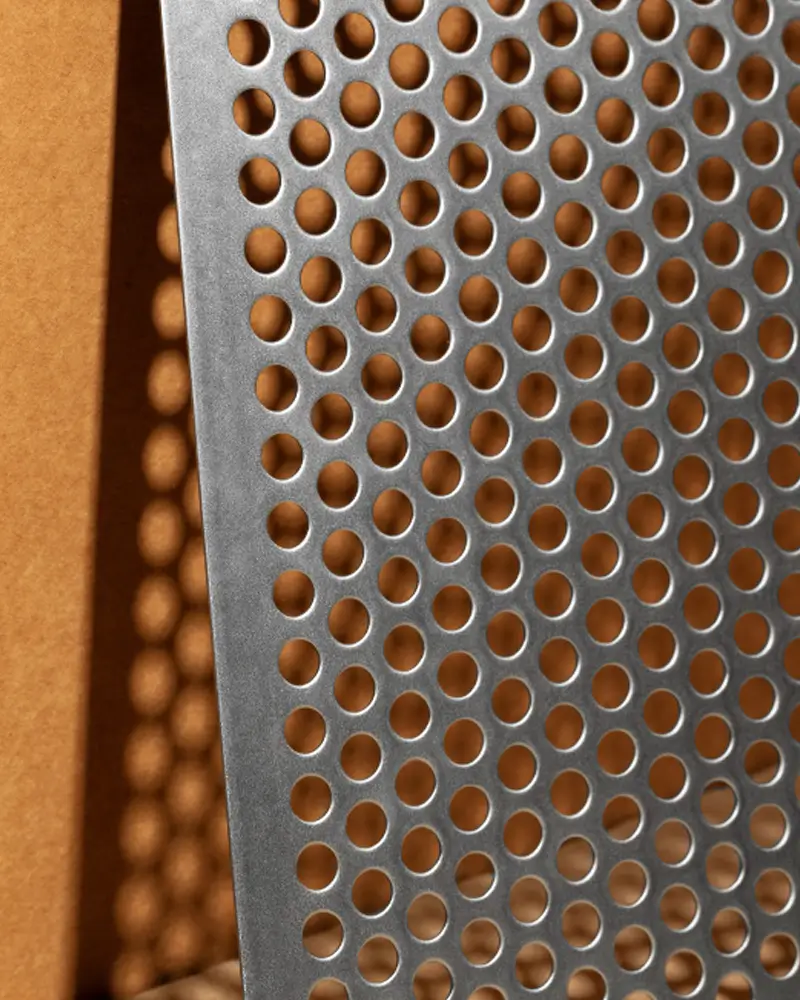

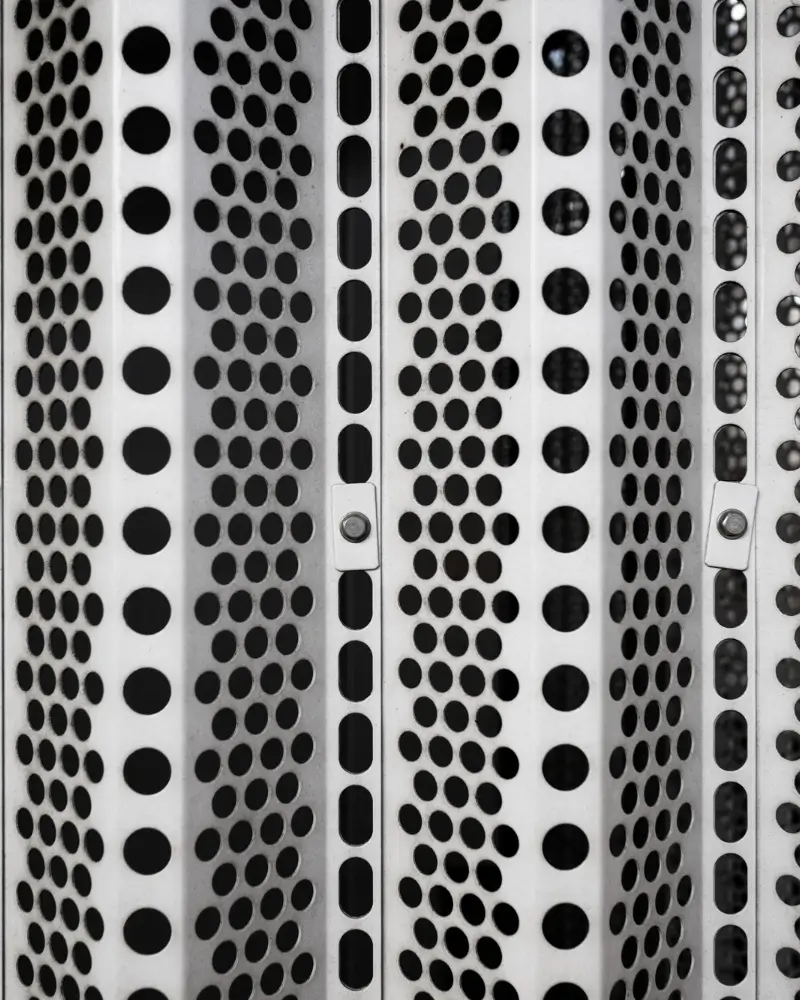

- Perforated sheets and ventilation grills

From decorative panels to industrial components, punching provides the strength, precision, and versatility needed across sectors.

Types of Metal Punching

At KKraft RADIX, we offer various punching methods to meet diverse design and production needs:

- Simple Hole Punching – Basic round or shaped holes punched through sheet metal.

- Nibbling – Creating complex contours or shapes using a series of overlapping punches.

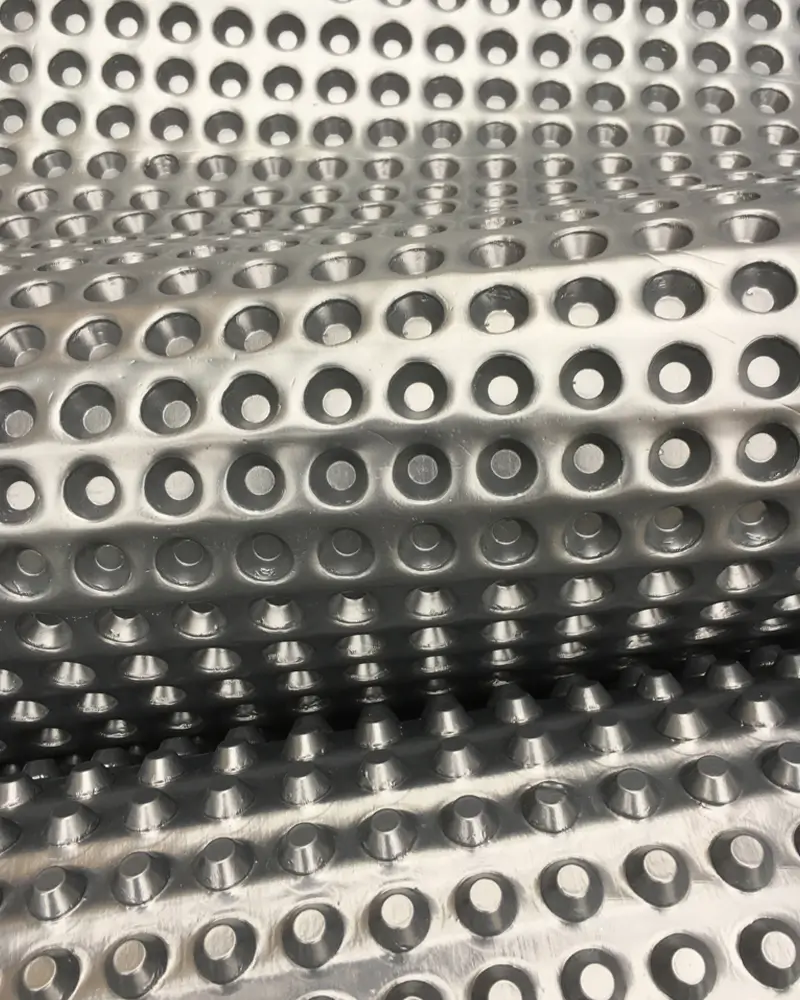

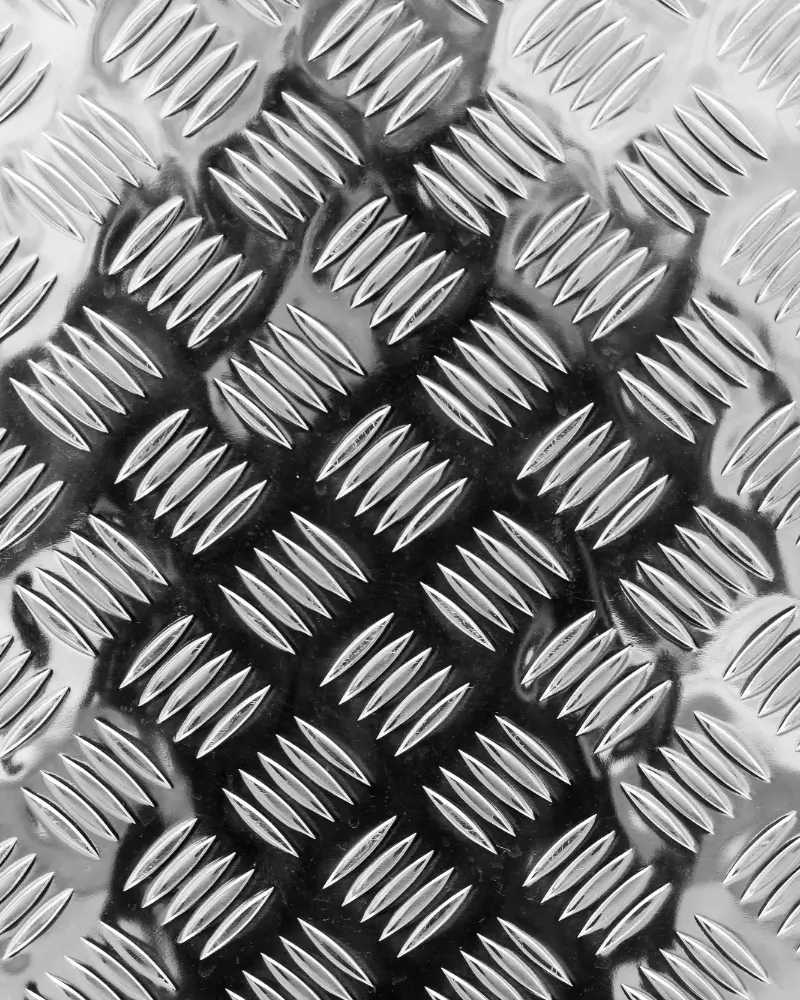

- Embossing/Forming – Adding raised or recessed features for structural or aesthetic purposes.

- Notching – Removing metal from the edge or corner of a sheet.

- Louver Punching – Creating slotted openings for ventilation and design elements.

Each technique can be combined or customized for your project’s unique requirements.

CNC Machining Services FAQs

Which materials can be punched at KKraft RADIX?

We punch a wide range of metals including mild steel, stainless steel, aluminum, copper, and galvanized steel. Custom materials can also be accommodated upon request.

How accurate is your punching process?

Our CNC punching machines achieve a dimensional accuracy of ±0.1 mm, ensuring every part meets precise tolerances.

Do you handle small or custom batch sizes?

We provide services for prototype development, custom one-offs, and large-scale production runs — all with the same level of care and precision.

Can punched parts be finished or further processed?

Yes. We offer deburring, bending, welding, powder coating, and assembly services, allowing you to receive fully finished components from a single source.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.