Steel Drilling

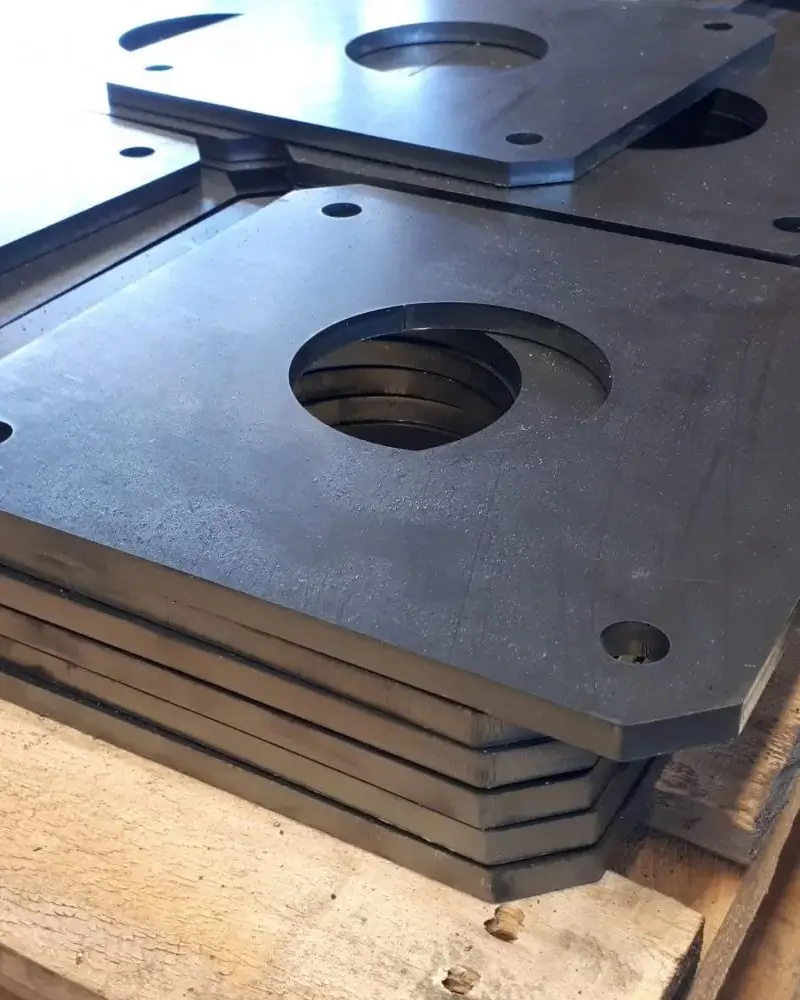

Precision holes are a non-negotiable requirement in most engineering projects. At KKraft RADIX, we provide fast, accurate, and clean steel drilling services for a variety of applications, from structural steel connections to machinery base plates. Using robust equipment and high-quality tooling, we ensure every hole is perfectly placed, correctly sized, and perpendicular to the surface.

We employ a range of drilling equipment to handle jobs of any scale, from one-off parts to large production runs.

- Equipment: Heavy-duty pedestal drills, radial arm drills, and magnetic base drills for on-site or large workpiece drilling.

- Operations: Standard through-holes, blind holes, counter-boring, and tapping/threading.

- Specialty: High-precision hole placement using jigs and digital readouts (DRO).

Capabilities

Hole Diameter

3 mm to 75 mm

Maximum Drilling Depth

Up to 200 mm

The KKraft RADIX Advantage

-

Positional Accuracy: We take precision seriously. Whether using a CNC layout or custom-made jigs, we guarantee that your bolt holes will line up perfectly every time.

-

Superior Hole Quality: We use sharp, premium drill bits and the correct cutting speeds, feeds, and coolant. This results in clean, round holes without the burrs and material deformation common with improper techniques.

-

Versatility: With our combination of workshop and portable magnetic base drills, we can drill holes in massive, immovable fabrications just as easily as small components.

-

Tapping & Threading: Save yourself a step. We can drill and then tap the holes to your specified thread size (e.g., M12, 1/2″ UNC), delivering a component that is ready for assembly.

What Does Steel Drilling Involve?

The process involves using a rotating, multi-point cutting tool (a drill bit) to cut a circular hole in a solid material. For a quality result, the workpiece must be securely clamped. We use a slower rotational speed (RPM) and higher pressure for larger diameter holes and harder materials, always with the application of cutting fluid to cool the bit and evacuate chips.

Materials We Drill

- Structural Steel (Beams, Columns, Plates, Angles)

- Stainless Steel

- Aluminum

- Hardened & Alloy Steels

- Brass, Bronze, and Copper

Examine the quality of their equipment. A rigid, heavy-duty drill press is essential to prevent the bit from “walking” or flexing, which leads to inaccurate hole placement and oval shapes. Ask if they use coolant and sharp tooling—drilling steel dry or with a dull bit can work-harden the material, making it extremely difficult to drill or tap later.

Advantage Over Other Methods

-

vs. Hole Punching: Drilling can be performed on much thicker and harder materials than punching. It also doesn’t cause the material deformation (dishing) around the hole that a punch can.

-

vs. Plasma/Laser Cutting Holes: Drilling produces a perfectly round hole with a machine-quality internal finish and no Heat-Affected Zone. This is critical for tapped holes or close-tolerance bearing fits. Plasma-cut holes are often tapered and have a rougher finish.

FAQs On Steel Drilling

Can you drill a hole in a hardened steel plate?

Yes, but it requires special carbide-tipped drill bits and very specific speeds and feeds. We have the expertise and tooling to do this successfully.

What is the typical tolerance on hole diameter and position?

For standard drilling, we can hold a positional tolerance of mm and a diameter tolerance of mm. Higher precision is possible upon request.

Do you offer tapping services for the holes you drill?

Yes, we provide a full range of tapping services for both metric and imperial threads. Let us know the thread specification you need.

Want To Get Your Project Fabricated?

Order metal fabrication from KKraft RADIX and experience the benefits yourself: 1-1 engineering support, payment terms for companies, a single point of contact, competitive pricing, on-time deliveries and quality control.