From the smartphone in your pocket to the skyscrapers that define our cities, nearly every modern product begins its life as a digital file. At the heart of this digital revolution is Computer-Aided Design (CAD), the foundational technology for turning ideas into reality. CAD refers to the use of specialized computer software to create, modify, and analyze intricate 2D drawings and 3D models of physical objects.

This guide explores the transformative capabilities of CAD, its undeniable advantages over traditional methods, and how it has become an indispensable tool for engineers, architects, and designers worldwide.

The Core Capabilities of Modern CAD Software

Before a single component is manufactured, its design must be perfected. CAD systems provide a virtual sandbox where this process can unfold with unprecedented speed and precision, moving far beyond the limitations of pen-and-paper drafting.

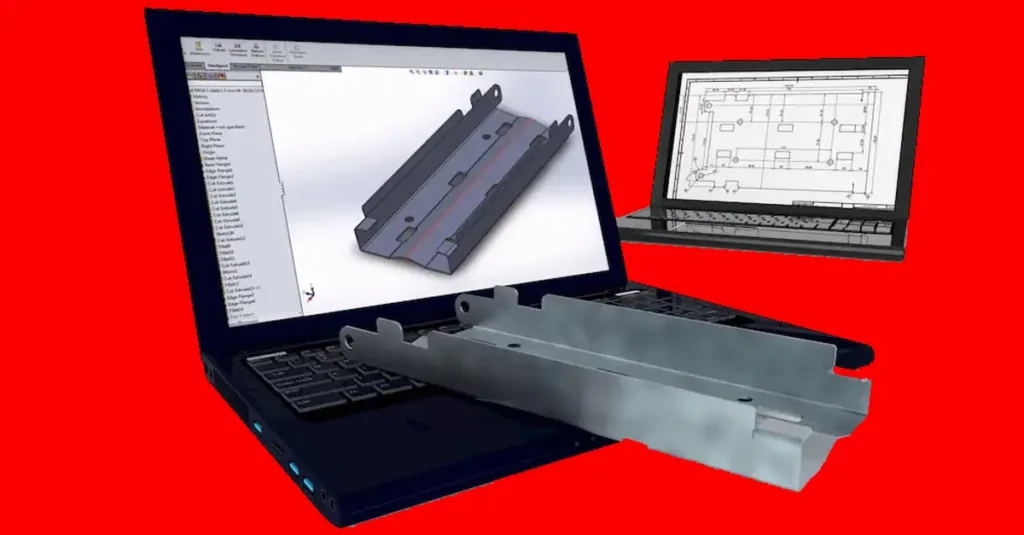

- Rapid 3D Modeling and 2D Drafting: Creating complex 3D models and production-ready 2D drawings is dramatically faster. What once took days of manual drafting can now be accomplished in hours.

- Digital Prototyping and Visualization: CAD allows designers to visualize a product from every angle. By applying materials, colors, and lighting, they can generate photorealistic renders that look just like the final product. This is crucial for marketing, client presentations, and internal design reviews before a physical prototype even exists.

- Pre-built Component Libraries: Engineers don’t need to reinvent the wheel for every nut, bolt, or bearing. CAD software often includes vast digital libraries of standard parts, allowing designers to simply select and insert components, saving time and ensuring standardization.

- Virtual Testing and Simulation: Many professional CAD platforms integrate tools for Finite Element Analysis (FEA). This allows engineers to simulate real-world conditions, testing a part’s strength against forces, vibrations, and heat without building a physical model. This capability helps identify potential design flaws early in the process.

Ultimately, a CAD system is more than a digital drawing board; it’s a comprehensive design environment that aligns perfectly with modern principles like lean manufacturing by minimizing waste and maximizing value.

Key Advantages of Integrating CAD into Your Workflow

The universal adoption of CAD is no accident. It offers a host of tangible benefits that give businesses a critical competitive edge.

1. Accelerating the Design Cycle: Speed and Time Savings

In today’s fast-paced market, time-to-market is everything. CAD software slashes development timelines by automating and simplifying complex tasks. For example, creating a flat pattern for a complex sheet metal part can be done with a single click. Furthermore, design iteration is effortless. A previous 3D model can be easily modified to create a new version, saving countless hours and allowing for rapid innovation.

2. Boosting Productivity and Throughput

The time saved with CAD directly translates into a massive increase in productivity. Studies have shown that teams adopting CAD can see an initial productivity increase of up to 3x, which can grow to nearly 10x as they master advanced features like simulation and automation. Instead of performing tedious manual calculations, engineers can focus on creative problem-solving and innovation, leading to better designs and a higher volume of completed projects.

3. Unmatched Precision and Accuracy

Manual sketching, no matter how skilled the drafter, cannot compete with the mathematical precision of CAD. The software allows for the creation of designs with extremely tight tolerances, ensuring that every part fits and functions exactly as intended. This is especially critical for complex surfaces and geometries that would be nearly impossible to represent accurately by hand. While the engineer’s oversight is still crucial for setting correct parameters, the software eliminates the risk of human drawing errors.

4. Minimizing Errors with Smart Tools

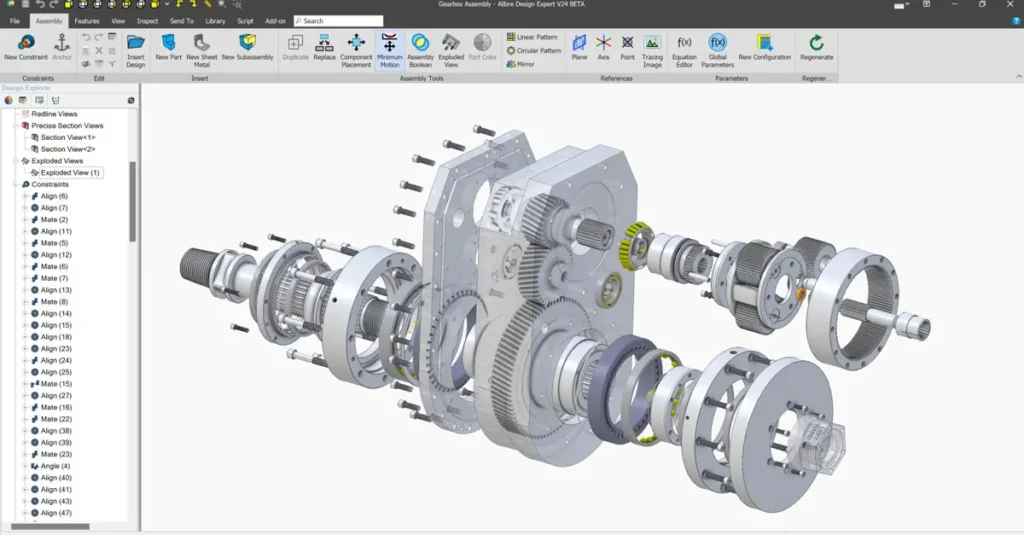

One of the most powerful features unique to 3D CAD is interference checking. This tool automatically analyzes an assembly to detect areas where parts collide or improperly intersect. Catching these clashes in the digital phase prevents costly manufacturing errors and rework down the line. Advanced systems can even create parametric relationships, where changing the dimension of one part (like a pin) automatically updates the corresponding part (like a hole) across the entire assembly and its associated 2D drawings.

5. Elevating Design Quality and Innovation

With the constraints of manual drafting removed, designers are free to explore more innovative and complex solutions. CAD provides the tools to bring even the most ambitious ideas to life, fostering creativity and leading to higher-quality, better-performing products. The resulting drawings are clean, legible, and standardized, which reduces ambiguity and ensures the final product accurately reflects the designer’s vision.

6. Simplifying Complexity: The Power of 3D Visualization

A set of 2D drawings (top, front, and side views) can be difficult to interpret, especially for non-technical stakeholders. A 3D CAD model, however, is intuitive. It can be rotated, sectioned, and exploded to show how components fit together. This makes it an invaluable tool for clear communication between designers, manufacturers, and clients. Many modern workshops even provide assemblers with tablets to view interactive 3D models, reducing assembly errors.

7. Seamless Collaboration Across Teams and Geographical Boundaries

CAD models are digital files, making them easy to share instantly with team members anywhere in the world. With the rise of cloud-based CAD, multiple users can collaborate on the same model in real-time, creating a “single source of truth” for the project. This is a game-changer for global companies and remote teams, ensuring everyone is always working with the most up-to-date design.

Beyond Design: CAD Integration with Manufacturing and Planning

The utility of a CAD model extends far beyond the design phase.

- Computer-Aided Manufacturing (CAM): CAD data seamlessly integrates with CAM software, which generates the toolpaths and machine code (like G-code) needed for CNC machining. This CAD/CAM integration automates much of the manufacturing preparation process, reducing lead times and ensuring parts are machined exactly to spec.

- Enterprise Resource Planning (ERP): The data-rich files from CAD, including detailed Bills of Materials (BOMs), can be fed into an ERP system. This connects the design data to the broader business operations, including inventory management, resource planning, and project scheduling, creating a more efficient end-to-end process.

Choosing the Right CAD Software

The CAD market is diverse, with tools tailored to different needs and budgets.

- Industry-Standard Professional Software: Programs like SolidWorks, Autodesk Inventor, and Solid Edge are powerful, feature-rich platforms used by professional engineers. They represent a significant investment but offer comprehensive toolsets for complex projects.

- Accessible and Cloud-Based Options: Software like Autodesk Fusion 360 has gained immense popularity for its flexible subscription model, powerful features, and strong cloud-based collaboration tools.

- Free CAD Software: For beginners, students, or hobbyists, programs like FreeCAD or the free versions of other software provide an excellent entry point to learn the fundamentals of 3D modeling without a financial commitment.

Conclusion: The Indispensable Role of CAD

While initial ideation may still begin with a simple hand sketch, modern product development is impossible to imagine without CAD. It has evolved from a simple drafting replacement into a holistic ecosystem for design, analysis, collaboration, and manufacturing. For any business looking to innovate, reduce costs, and accelerate its time-to-market, embracing Computer-Aided Design isn’t just an option—it’s essential for survival and success.

KKraft RADIX has an experienced team of CAD engineers that will design your project and set it for production at our workshop. If you need more details about our design and fabrication skills, reach out to us on +254 736 900 111 or write us an email at steel@kkraftradix.com.